TECHNOLOGY

Technological Breakthrough

The common microwave oven has a cooking cavity known technically as a multimode applicator, “multimode” meaning a metal box of fixed dimensions that can support a number of resonant modes at a given frequency. The current magnetron has a typical oscillating frequency of around 2455MHz with capabilities of variation within a bandwidth of ±5MHz for a typical microwave oven. However, these mode patterns are purely theoretical and represent an empty cavity condition. When food is placed within the cavity, and dependent on its shape and container type, the mode pattern changes. Then, when the food is heated, its electrical (relative permittivity and dielectric constant) properties change, causing the mode patterns to change even further.

To minimize these effects most ovens have either a turntable or mode stirrer. The mode stirrer as the name implies, rotates axially about the microwave launch plane, providing a continuously variable impedance change to the incoming microwave energy. This impedance change causes the magnetron to oscillate at different frequencies within its narrow bandwidth, thus satisfying the conditional mode change.

The turntable on the other hand has two functions: Firstly, because of its physical distance from the microwave launch plane, the rotating food becomes the mode stirring mechanism but, in this case, has less impact on the magnetron’s frequency variation. Secondly, and to compensate for this, the food travels through constantly changing microwave energy fields, improving the heat distribution.

In both methods there is a direct coupling relationship between the microwave energy source and the food load to be heated.

All ovens have different sized cavities, meaning they require their own dedicated microwave coupling system. So the challenge was to develop a standard system that could be fitted to any size of oven, with the minimum of changes required. With this in mind, a new microwave coupling system was designed that would produce a constant impedance source, irrespective of food load, and allow microwave energy transfer to be made in the most effective and unrestricted manner.

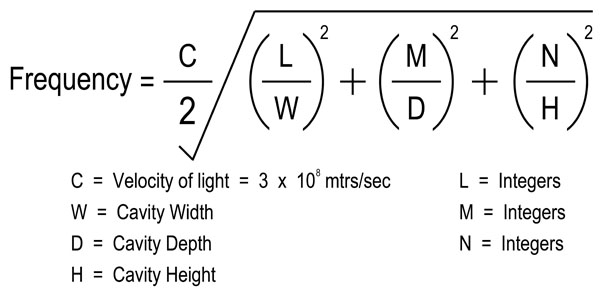

The system is known as the “Multi-Entry-Mode-Resonator” or for short “Mode Resonator”. It gives unparalleled vertical and lateral heating distribution, regardless of shelf position, and is unaffected by the use of metal baking utensils or multiple metal shelves. Many more frequencies are excited with the mode resonator system giving rise to a much more even energy uniformity. It follows the standard equation for resonance:

Reducing the sensitivity of microwave oven heating and cooking performance to load volume, load placement and load properties has been a longstanding challenge for microwave and microwave-convection oven designers. To begin with, conventional design problems and solution methods were reviewed to provide greater insight into the challenges and optimum operation of a microwave oven. A new design strategy was introduced, using a special load isolating and energy modulating device called a transducer-exciter. It contains a microwave launch box and iris, a phase amplitude and frequency modulator, and a mode coupling matchplate designed to provide spatially distributed energy coupling to the oven.